About JR

JR (Guangdong)New Material CO., LTD

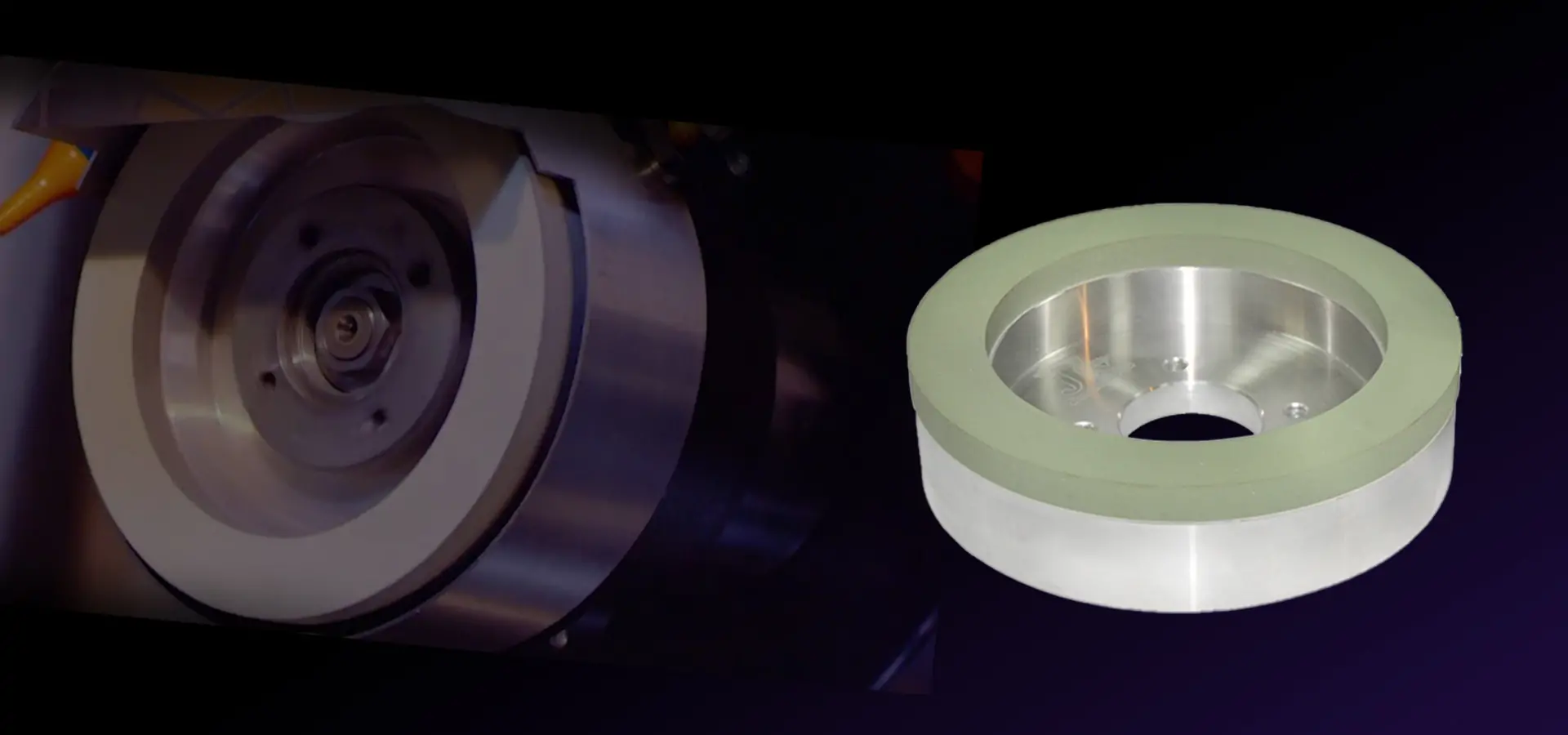

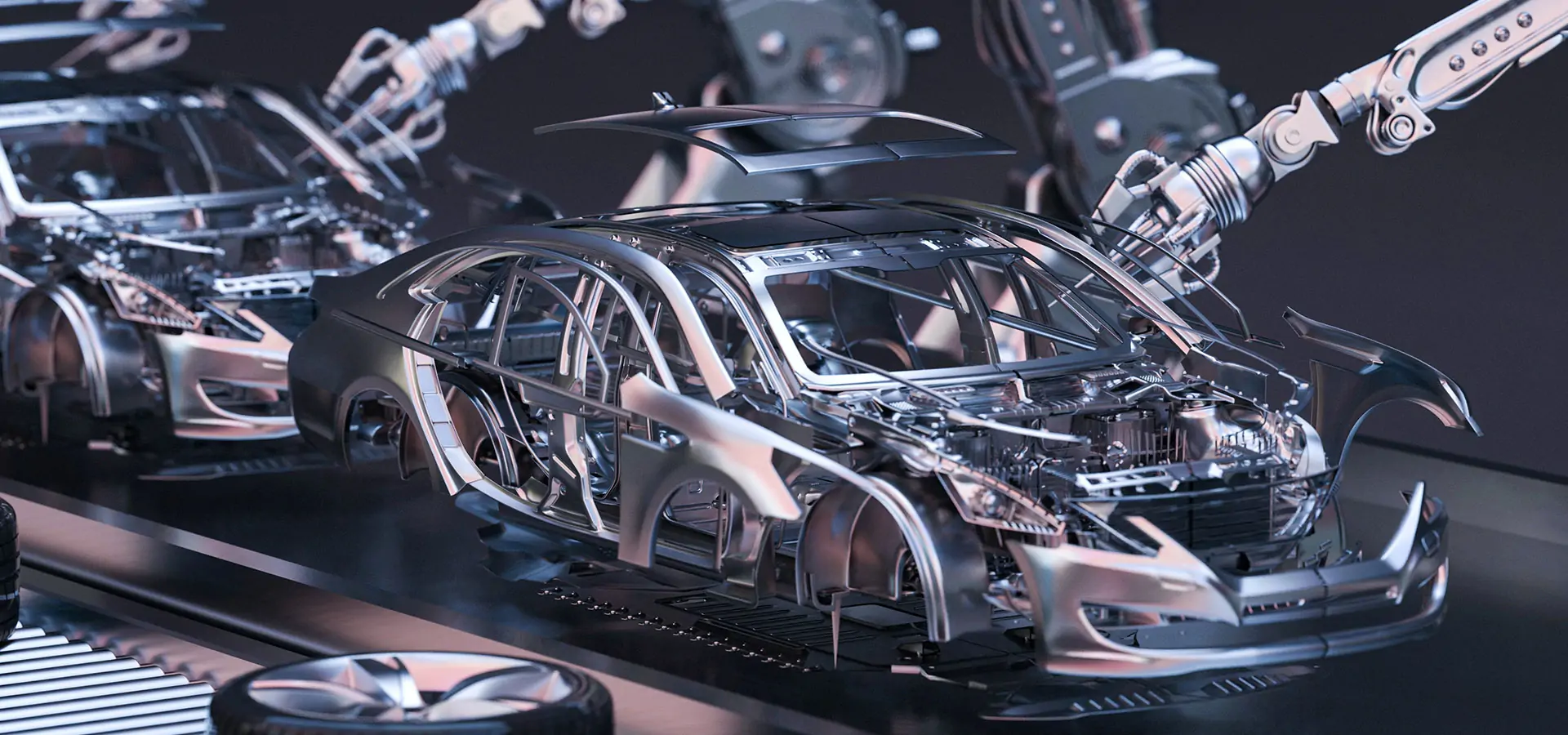

was founded in 1992 and running as a professional manufacturer and trustworthy marketer, which has a long and proud heritage of innovation. We are located in the provincial capital of the most prosperous part of China, Guangzhou city, products is vitrified bond grinding wheel,Electroplating cutting disc,Camshaft grinding wheel,CBN grinding wheel,resin bond grinding wheel,Dental milling burs.and send our products and solutions to our global clients in all kinds of industries such as stone, ceramic, glass, precious stone, diamond, hard metal, high-tech fields including automotive components, precision mechanical parts, electronic and optical glass.

Founded in 1992

30 years experience in diamond /CBN tools

Products is Resin Grinding Wheel,resin bond grinding wheel,Camshaft grinding wheel,electroplated grinding wheel,CBN grinding wheel,Dental milling burs,Electroplating cutting disc.In the end of 2019, due to the development of the company, the company name was changed from ". JR (Guangdong)New Material CO., LTD ". to "JR(Guangdong) New Material Incorporated Company."

A trusted expert in diamond and CBN grinding solutions

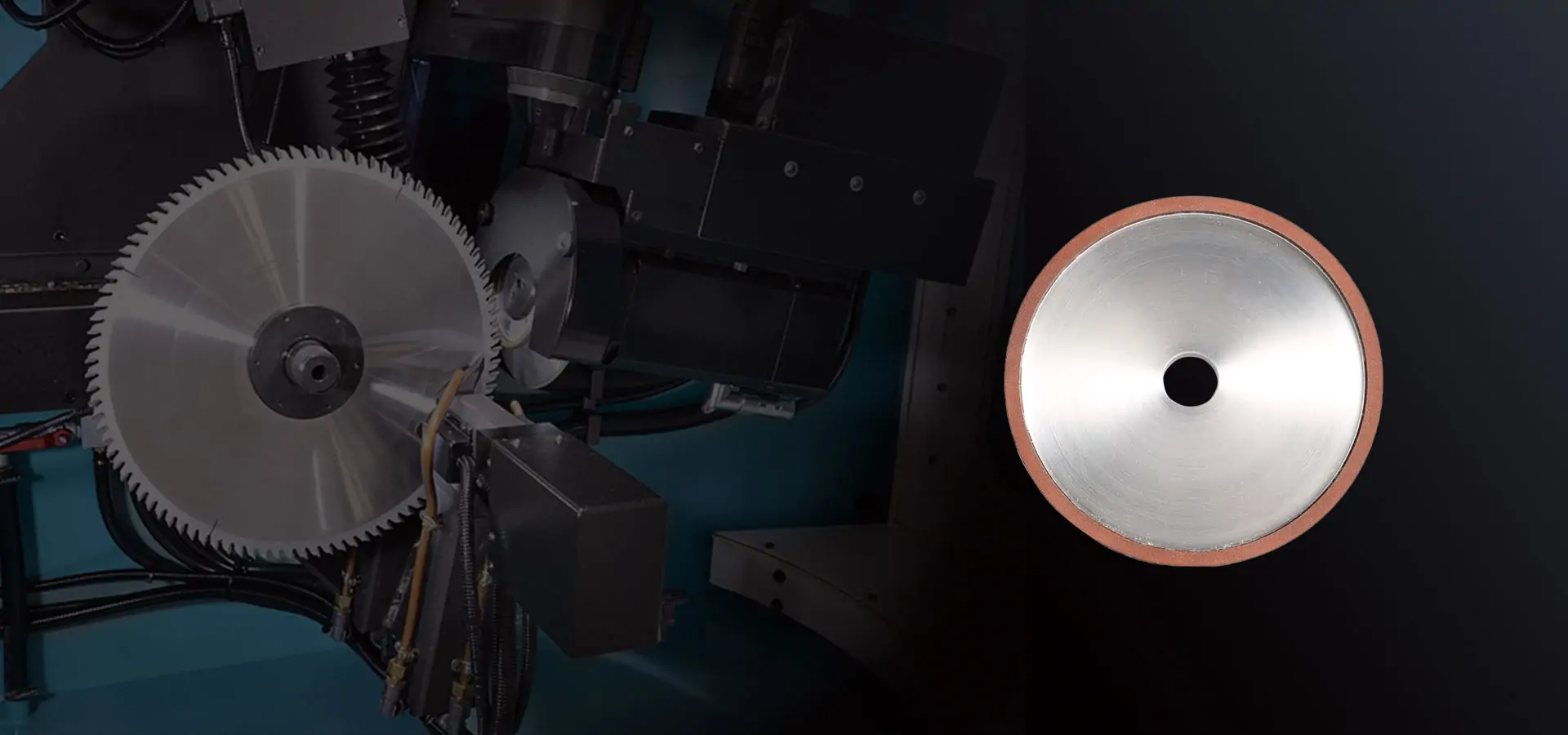

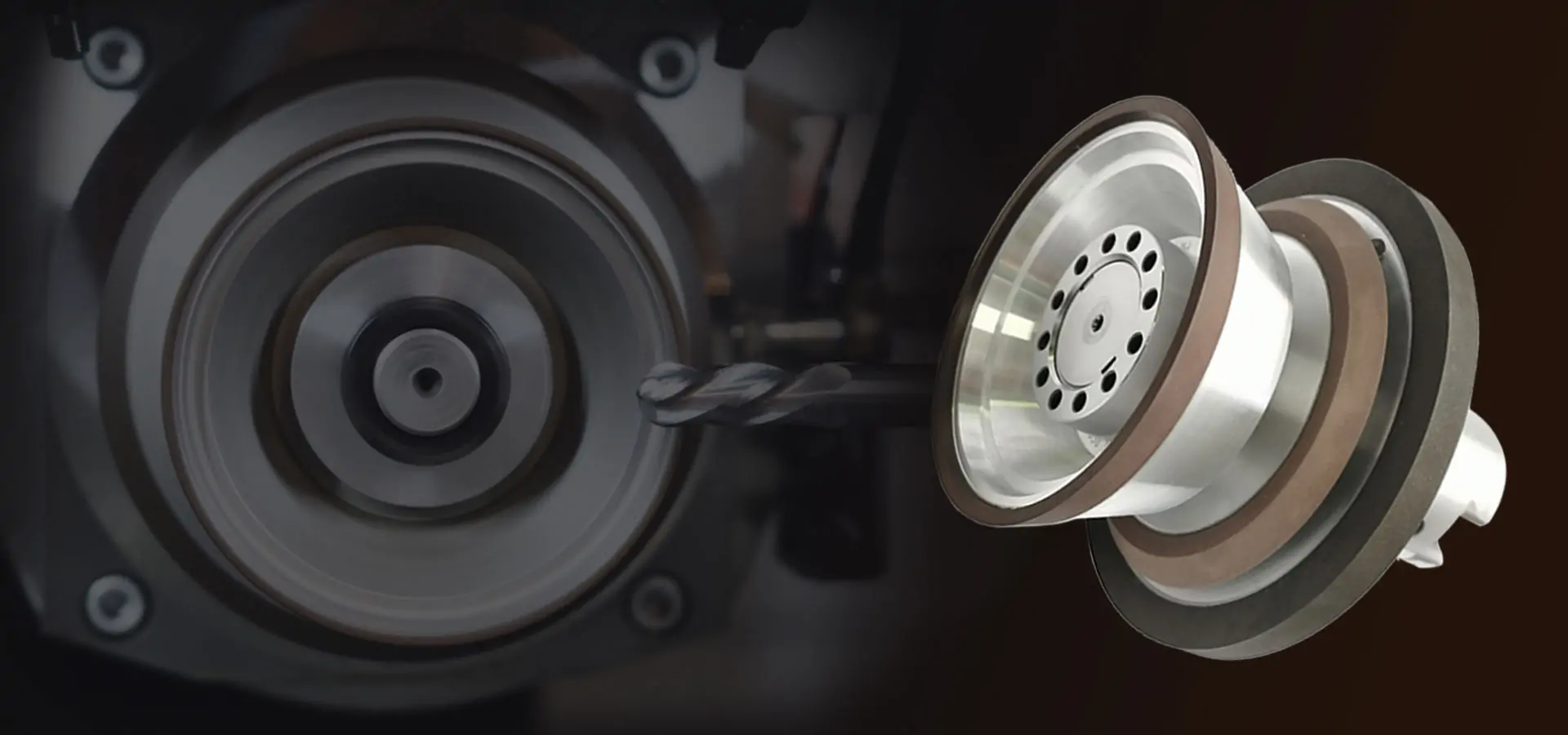

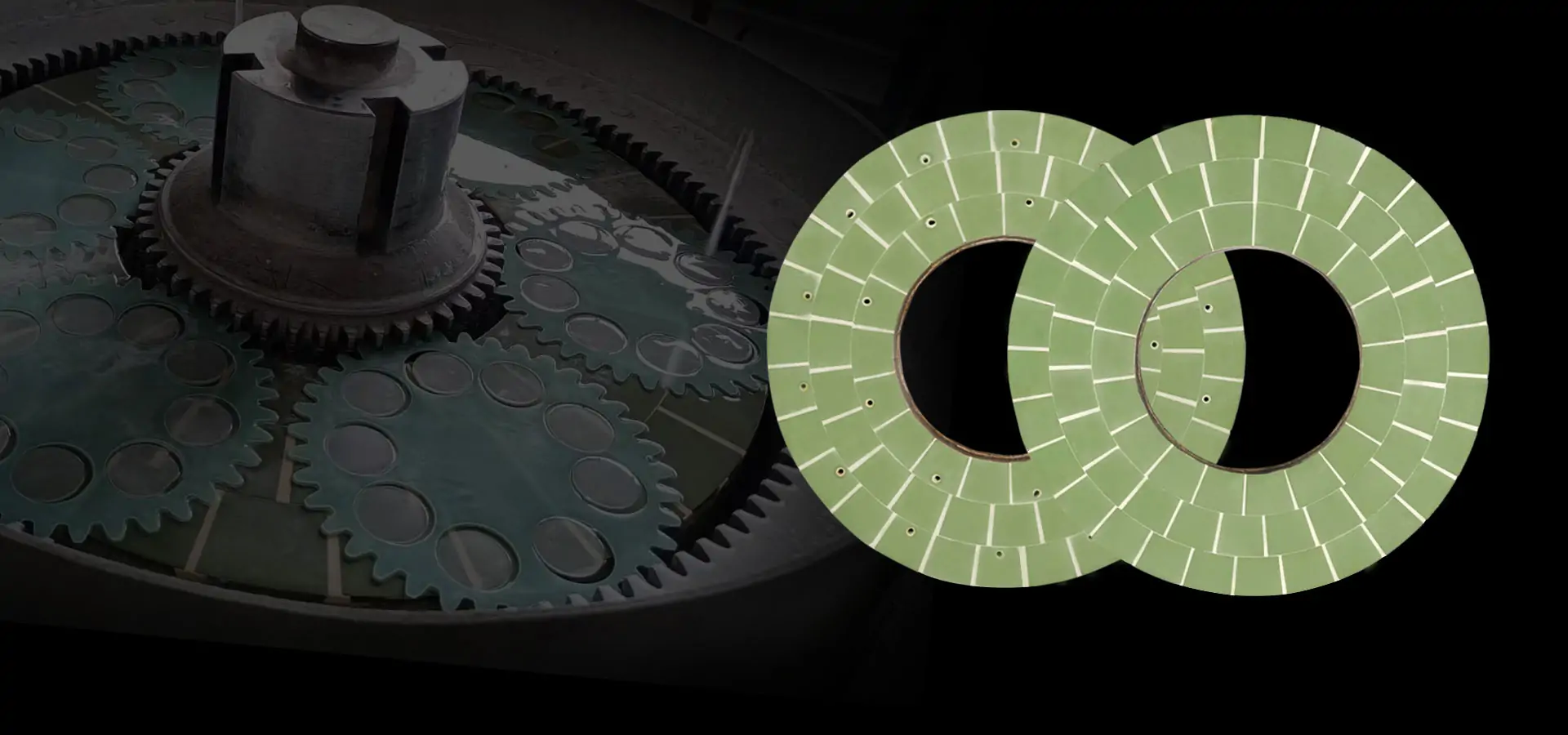

Diamond & CBN Centerless Grinding Wheels

The company's main products are Resin Grinding Wheel,resin bond grinding wheel,Camshaft grinding wheel,electroplated grinding wheel,CBN grinding wheel,Dental milling burs,Electroplating cutting disc etc.

Actively participating in promotion and Expo in this field during these years of our expansion, JR Company has built up an amicable and reciprocal business relationship with many large-scaled factories home and abroad by our products of stable quality, excellent performance and technological advantages. Meanwhile, we are cordially welcome your visit, inspection and consultancy!