Sapphire processing industry

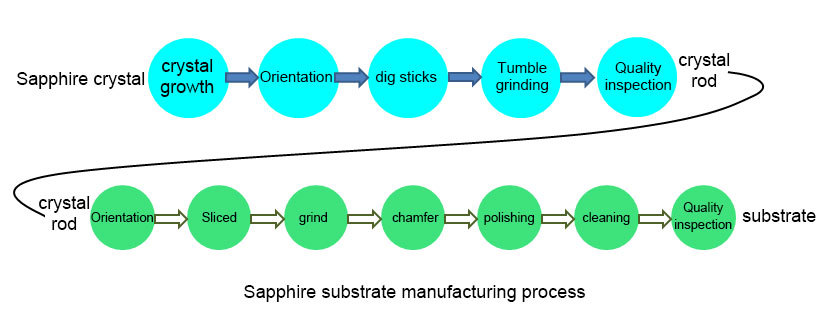

The raw material of sapphire substrate is crystal rod, which is processed by sapphire crystal. The manufacturing process is as follows:

Sapphire crystal rod processing flow:

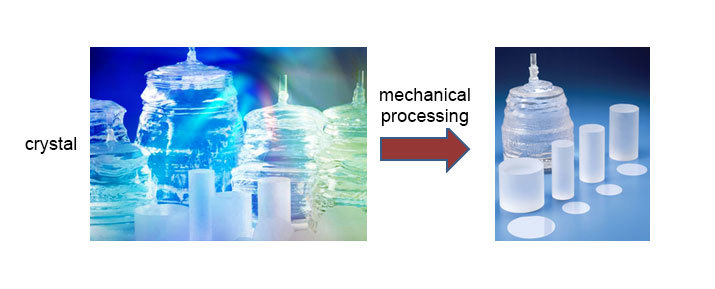

Long crystal: use long crystal furnace to grow single crystal sapphire crystal with large size and high variety

Orientation: ensure the correct position of sapphire crystal on the rod cutting machine, which is convenient for rod cutting processing

Take out the sapphire crystal rod: take out the sapphire crystal rod from the sapphire crystal in a specific way. The nesting knife produced by our company has high efficiency, high precision, long service life and low cost.

Roll grinding: use the cylindrical grinder to grind the outer circle of the crystal rod to obtain the accurate dimensional accuracy of the outer circle. Using the superhard material (Diamond / CBN) grinding wheel and grinding disc produced by our company can greatly improve the product accuracy, processing efficiency and save the cost.

Quality inspection: ensure the quality of the crystal bar and whether the size and orientation of the crystal bar after removal comply with the customer's regulations.

Substrate manufacturing process:

Orientation: accurately locate the position of sapphire crystal rod on the slicer to facilitate accurate slicing

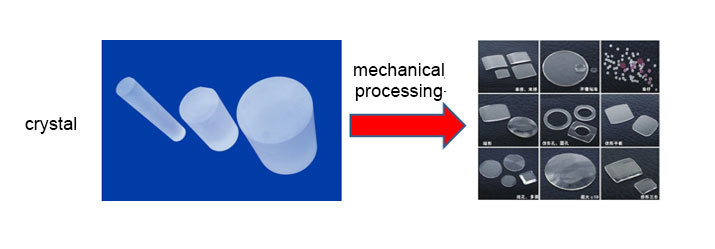

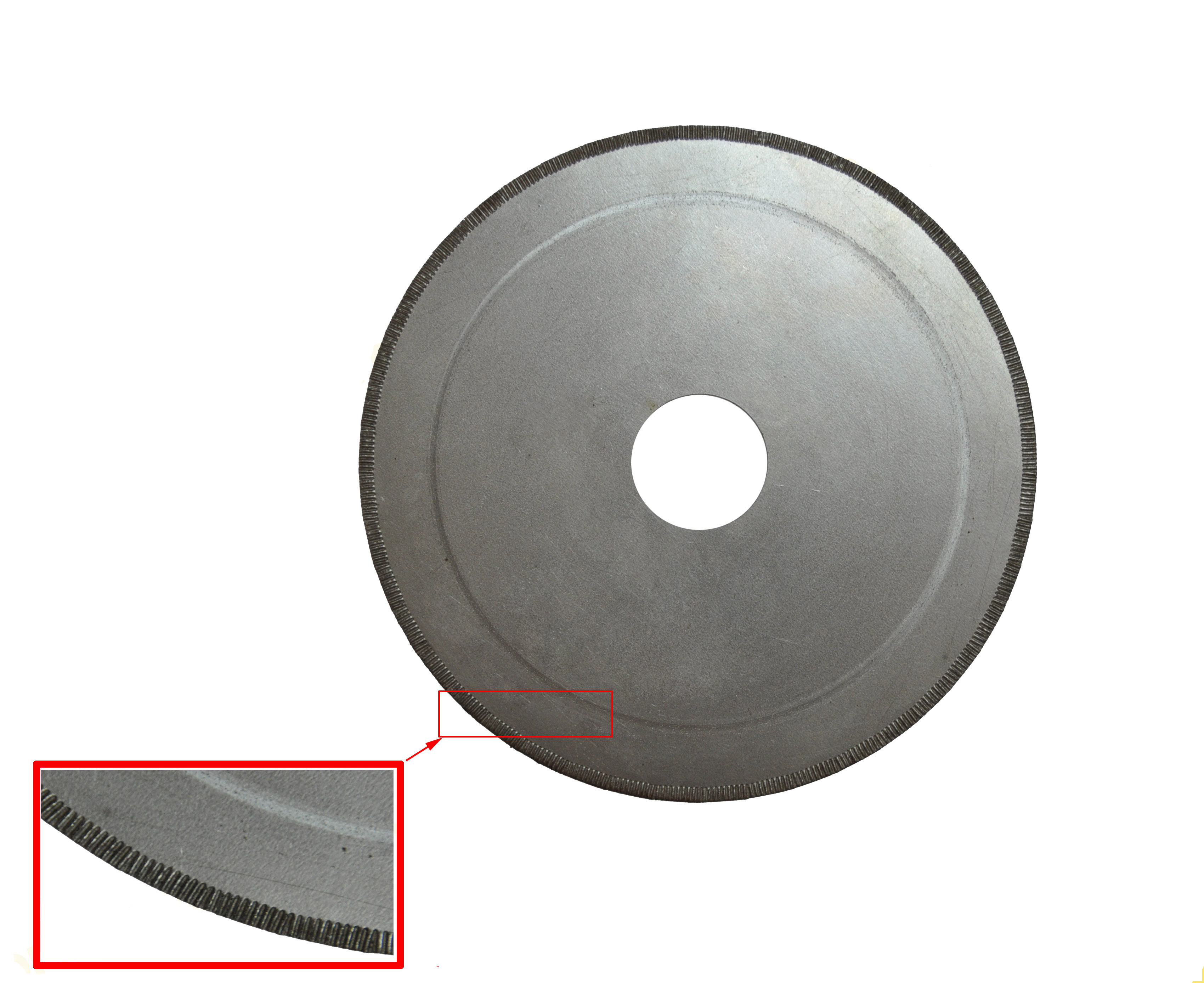

Slicing: cut the sapphire crystal rod into thin chips. The oblique tooth cutting piece and straight tooth cutting piece produced by our company have the advantages of high efficiency, high precision and low cost.

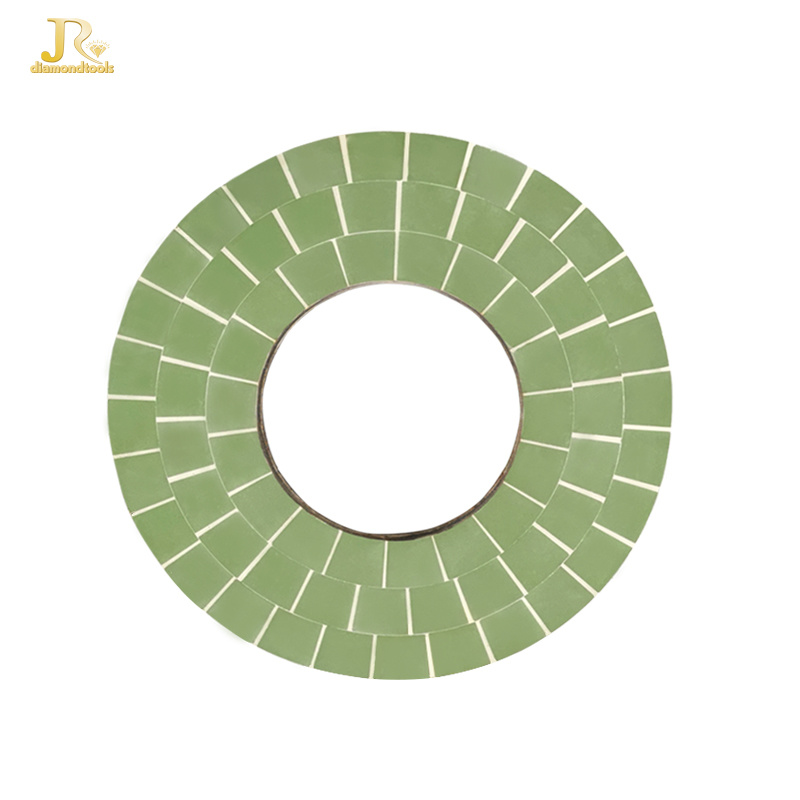

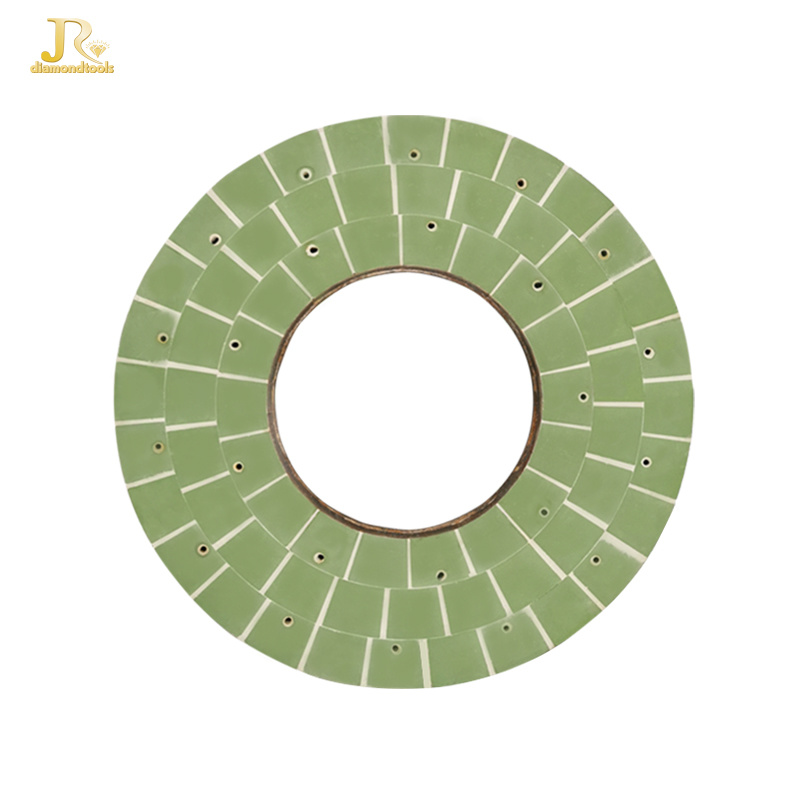

Grinding: remove the chip cutting damage layer caused by slicing and improve the flatness of the chip. Using the ceramic double face diamond grinding disc produced by our company can effectively improve the production efficiency, reduce the production cost and improve the product accuracy. (learn more about ceramic double face diamond grinding disc)

Chamfering: trim the wafer edge into a circular arc to improve the mechanical strength of the wafer edge and avoid defects caused by stress concentration. The chamfering device and round edge wheel produced by our company have the advantages of high efficiency, high precision and low cost.

Polishing: improve the wafer roughness and make its surface reach the accuracy of epitaxial wafer epitaxial level. Our company's diamond powder, grinding paste and polishing fluid have the characteristics of high precision and high efficiency.

Cleaning: remove the pollutants on the wafer surface (such as micro dust particles, metal, organic dirt, etc.).

Quality inspection: use high-precision testing instruments to test the wafer quality (flatness, surface micro dust particles, etc.) to meet customer requirements.

key word:

Related applications