CNC tool processing industry

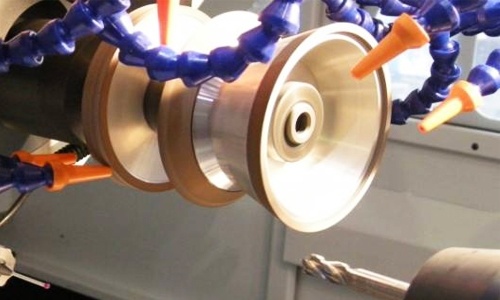

With the continuous improvement of the overall quality requirements of cemented carbide tools in automotive engines, aerospace, mold industry, consumer electronics and other high-end precision machining fields, the requirements for precision tool grinding are also higher and higher, and the grinding wheel, as an important part, plays a very important role. Jinrui is equipped with Walter, ANCA, EWAG, Vollmer, ROLLOMATIC, Schutte, SCHNEEBERGER and other foreign CNC grinding machines as well as domestic CNC tool grinding machines to provide high-quality tool grinding wheels, which can effectively improve grinding efficiency, improve tool surface quality, enhance tool life and reduce comprehensive cost.

CNC tools refer to the tools processed and formed in CNC equipment, including drill bits, milling cutters, reamers, taps, etc. Its materials mainly include cemented carbide, high-speed steel, stainless steel, etc.

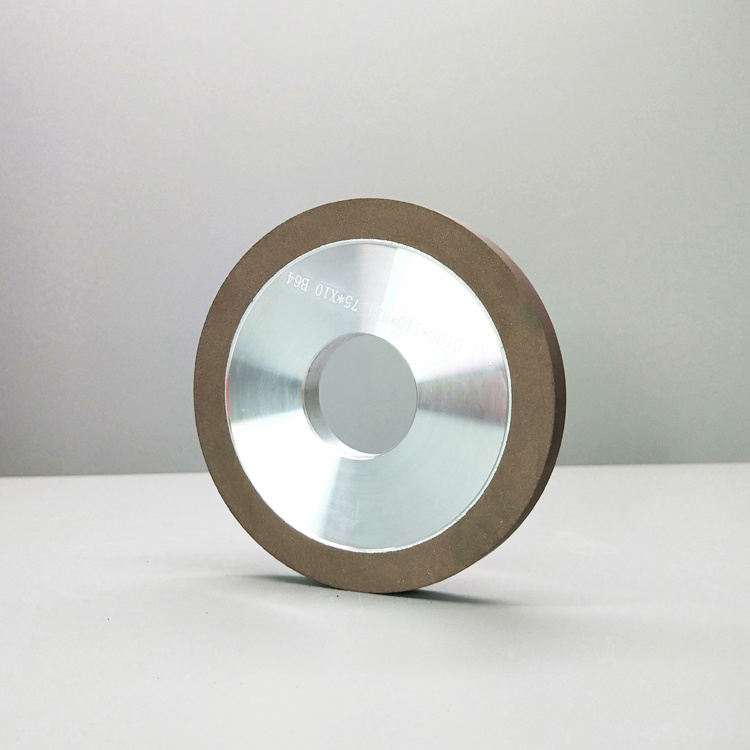

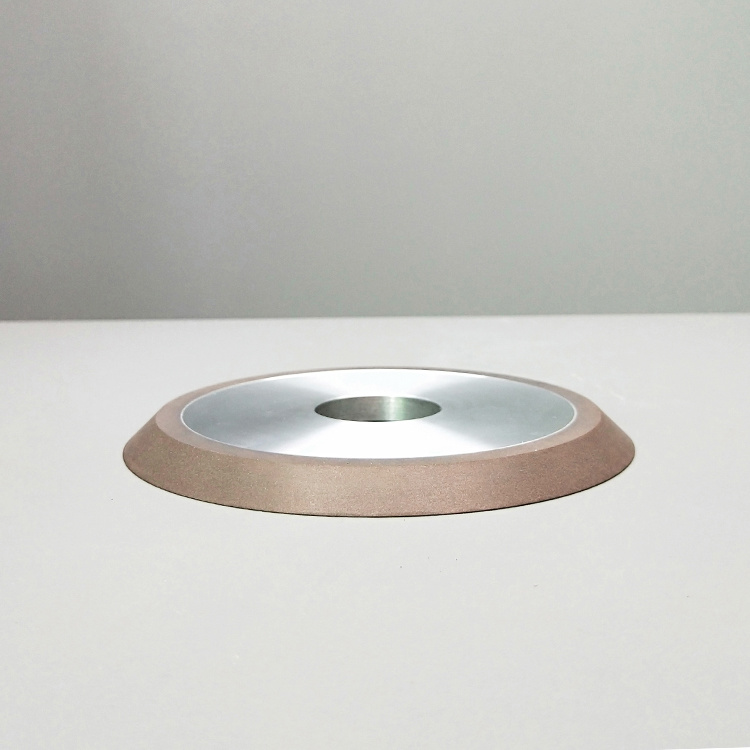

Grinding wheel model for milling cutter slotting: 1A1, 1v1, 14a1

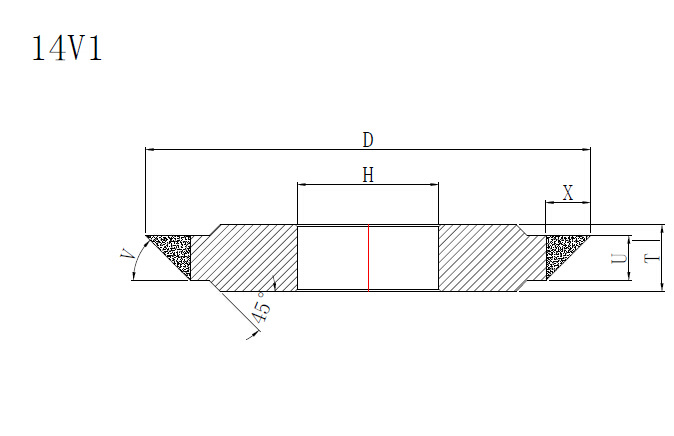

Grinding wheel models for milling cutter form grinding: 1v1, 12v9, 14v1

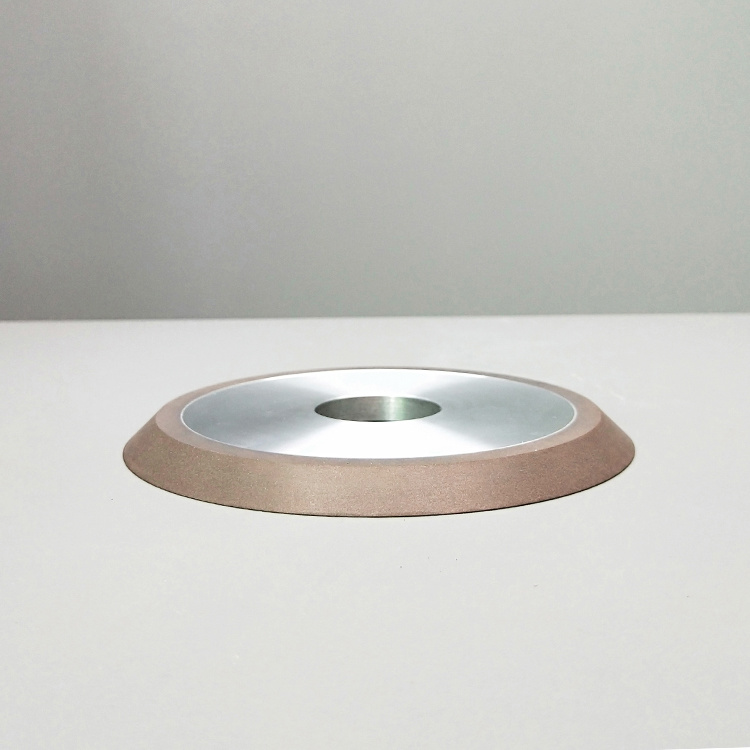

Grinding wheel for back angle grinding of milling cutter model: 11v9, 11A2

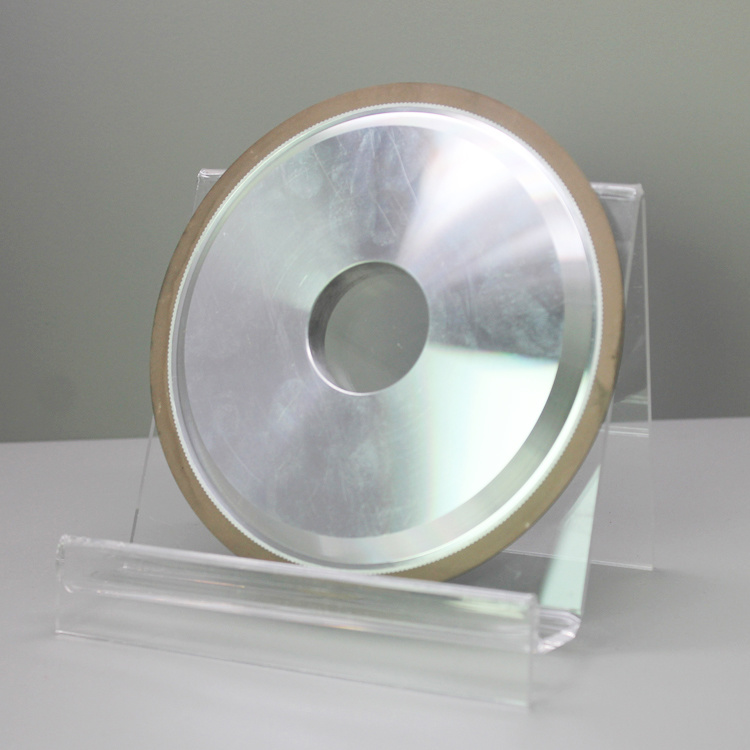

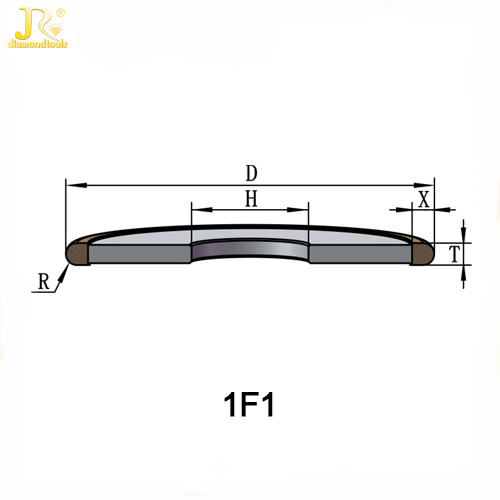

Model of grinding wheel for bit slotting: 1F1, 14F1

key word:

Related applications

JR (Guangdong)New Material CO., LTD

-

Tel:13903066017

-

E-mail:sales@jrdiamondtools.com

-

Add: Building C28, Huachuang Industrial Park, Jinshan Avenue, Shiji Town, Panyu, Guangzhou-511450, China