Dental milling bur

1. Material: The finest grain carbide;

2. Coating: CVD real diamond coated layer;

3. Application: Compatible with most dental CAD/CAM milling machines;

4. Cutting Lifespan: 40pc to 120pc workpiece per bur;

5. Higher efficiency: Super smooth milling surfaces and higher feed rate;

6. Traceability: Each origin dental milling bur has a proven track record of performance and dependability;

7. HS Code: 82077010;

8. Support customization

Classification:

Products

Electroplated Diamond&CBN Grinding Tools

Product description

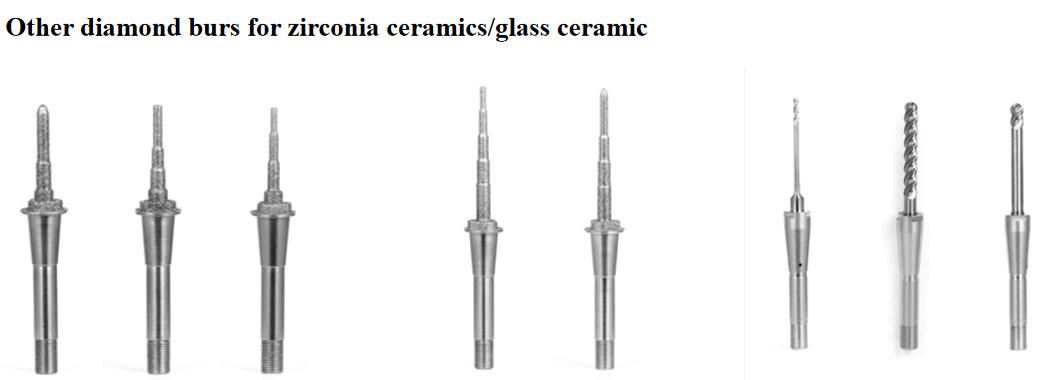

We provide a range of dental milling burs suitable for most CAD/CAM milling machines. Our burs come with different coatings to ensure excellent milling performance on difficult materials, thin areas, and complex shapes. We offer both high-end and more affordable options that are longer lasting than many comparable tools on the market. Our milling burs are compatible with a wide variety of milling machines, such as Arum,Roland, VHF,MCX5,Imes-icoer 250i,Imes icore 350, XTCERA 300/400,AIM,Dentium, Linggong ,Jiansan,Other diamond burs for zirconia ceramics/glass ceramic and more. If you're looking for inexpensive, long-lasting milling tools, you've come to the right place! So, whether you need CAD/CAM milling burs or economical long-life burs, we have got you covered.

Benefits of dental milling burs:

1. Precision: Diamond dental milling burs are extremely precise, allowing for highly detailed and accurate dental work.

2. Durability: Diamonds are one of the hardest substances on earth, which makes diamond dental milling burs incredibly durable and long-lasting.

3. Versatility: Diamond dental milling burs can be used for a wide range of dental procedures, including crown and bridge work, implant abutments, and more.

4. Speed: Diamond dental milling burs are designed to work quickly and efficiently, helping to reduce the time it takes to complete dental work.

5. Smoothness: Diamond dental milling burs produce extremely smooth and polished surfaces, which is essential for ensuring patient comfort and preventing irritation or inflammation.

Overall, diamond dental milling tools offer a range of benefits that make them an excellent choice for dental professionals looking to provide high-quality dental care.

Product type:

1. Arum

| Arum |  |

Head diameter | Cutter head length | Shank diameter | Total length |

| 2.5 | 13.75 | 4 | 45 | ||

| 1.5 | 10 | 4 | 45 | ||

| 1.0 | 10 | 4 | 45 | ||

| 0.6 | 8.5 | 4 | 45 | ||

| Durability | Stable processing of 40 -120 teeth | ||||

| Application | Fits for Arum dental milling machine | ||||

| texture of material | Tungsten steel | ||||

| coating | CVD real diamond coated layer | ||||

| Place of Origin | Dongguan | ||||

| size | The dimensions in the drawing can also be customized according to sample | ||||

2. Roland

| Roland |  |

head diameter | Cutter head length | Shank diameter | Total length |

| 2.5 | 15 | 3 | 40 | ||

| 1.5/0.6 | 9.3 | 3 | 40 | ||

| 1.0 | 6 | 3 | 40 | ||

| Durability | Stable processing of 40 -120 teeth | ||||

| Application | Compatiable for Roland dental milling system | ||||

| material | Tungsten steel | ||||

| coating | CVD real diamond coated layer | ||||

| Place of Origin | Dongguan | ||||

| size | The size in the picture can also be customized | ||||

3. VHF

| VHF |  |

Head diameter | Cutter head length | Shank diameter | Total length |

| 0.6 | 8.6 | 3 | 35 | ||

| 1.0 | 8.6 | 3 | 35 | ||

| 2.0 | 15.9 | 3 | 35 | ||

| Durability | Stable processing of 40 -120 teeth | ||||

| Application | Suitable for VHF grinding equipment | ||||

| material | Tungsten steel | ||||

| coating | CVD real diamond coated layer | ||||

| Place of Origin | Dongguan | ||||

| size | The size in the picture can also be customized | ||||

4. Sirona MC X5

| MCX5 |  |

Head diameter | Cutter head length | Shank diameter | Total length |

| 2.2 | 15.46 | 3 | 37.4 | ||

| 1.2 | 12.50 | 3 | 36.4 | ||

| 1.4 | 14.43 | 3 | 35.4 | ||

| Durability | Stable processing of 40 -120 teeth | ||||

| Application | Fit Sirona MC X5 grinding equipment | ||||

| material | Tungsten steel | ||||

| coating | CVD real diamond coated layer | ||||

| Place of Origin | Dongguan | ||||

| size | The size in the picture can also be customized | ||||

5. lmes-icoer250

| lmes-icoer250 |  |

Head diameter | Cutter head length | Shank diameter | Total length |

| 2.5 | 14.4 | 3 | 42 | ||

| 1.0 | 10.13 | 3 | 43 | ||

| 0.6 | 9.93 | 3 | 43 | ||

| Durability | Stable processing of 40 -120 teeth | ||||

| Applicable equipment | Suitable for lmes-icoer250 grinding equipment | ||||

| material | Tungsten steel | ||||

| coating | diamond coating | ||||

| Place of Origin | Dongguan | ||||

| size | The size in the picture can also be customized | ||||

6. lmes-icoer350

| lmes-icoer350 |  |

Head diameter | Cutter head length | Shank diameter | Total length |

| 2.5 | 14.8 | 6 | 40 | ||

| 1.0 | 10.2 | 6 | 40 | ||

| 0.6 | 10 | 6 | 40 | ||

| Durability | Stable processing of 40 -120 teeth | ||||

| Applicable equipment | Suitable for lmes-icoer350 machines | ||||

| material | Tungsten steel | ||||

| coating | diamond coating | ||||

| Place of Origin | Dongguan | ||||

| size | The size in the picture can also be customized | ||||

7. XTCERA 300/400

| XTCERA 300/400 |  |

Head diameter | Cutter head length | Shank diameter | Total length |

| 2.5 | 16 | 3 | 45 | ||

| 1.0 | 10 | 3 | 45 | ||

| 0.6 | 12 | 3 | 45 | ||

| Durability | Stable processing of 40 -120 teeth | ||||

| Applicable equipment | Suitable for XTCERA 300/400 systems | ||||

| material | Tungsten steel | ||||

| coating | diamond coating | ||||

| Place of Origin | Dongguan | ||||

| size | The size in the picture can also be customized | ||||

8. AIM

| AIM |  |

head diameter | Cutter head length | Shank diameter | Total length |

| 2.0 | 14.71 | 4 | 38 | ||

| 1.0 | 10 | 4 | 34 | ||

| 0.5 | 2.37 | 4 | 36 | ||

| Durability | Stable processing of 40 -120 teeth | ||||

| Applicable equipment | Suitable for AIM grinding equipment | ||||

| material | Tungsten steel | ||||

| coating | diamond coating | ||||

| Place of Origin | Dongguan | ||||

| size | The size in the picture can also be customized | ||||

9. Dentium

| Dentium |  |

head diameter | Cutter head length | Shank diameter | Total length |

| 0.6 | 19.8 | 6 | 50 | ||

| 1.0 | 19.8 | 6 | 50 | ||

| 2.0 | 19.8 | 6 | 50 | ||

| Durability | Stable processing of 40 -120 teeth | ||||

| Applicable equipment | Suitable for Dentium grinding equipment | ||||

| material | Tungsten steel | ||||

| coating | diamond coating | ||||

| Place of Origin | Dongguan | ||||

| size | The size in the picture can also be customized | ||||

10. Jill Bach / Launca

| Jill Bach / Launca |  |

Head diameter | Cutter head length | Shank diameter | Total length |

| 1.8 | 14 | 3 | 43 | ||

| 1.4 | 14 | 3 | 43 | ||

| 1.0 | 13.65 | 3 | 43 | ||

| 0.4 | 6.3 | 3 | 43 | ||

| Durability | Stable processing of 40 -120 teeth | ||||

| Applicable equipment | Suitable to Jill Bach / launca grinding equipment | ||||

| texture of material | Tungsten steel | ||||

| coating | Diamond coating | ||||

| Place of Origin | Dongguan | ||||

| size | The dimensions in the drawing can also be customized according to samples | ||||

11. Ling Gong

| Ling Gong |  |

head diameter | Cutter head length | Shank diameter | Total length |

| 0.6 | 10 | 4 | 45 | ||

| 1.0 | 10 | 4 | 45 | ||

| 2.0 | 16 | 4 | 45 | ||

| Durability | Stable processing of 40 -120 teeth | ||||

| Applicable equipment | Suitable for Ling Gong grinding equipment | ||||

| material | Tungsten steel | ||||

| coating | diamond coating | ||||

| Place of Origin | Dongguan | ||||

| size | The size in the picture can also be customized | ||||

12. Jian San

| Jian San |  |

head diameter | Cutter head length | Shank diameter | Total length |

| 2.5 | 16.93 | 6 | 50 | ||

| 2.0 | 16.93 | 6 | 50 | ||

| 1.0 | 12.92 | 6 | 50 | ||

| Durability | Stable processing of 40 -120 teeth | ||||

| Applicable equipment | Suitable for Jian San grinding equipment | ||||

| material | Tungsten steel | ||||

| coating | diamond coating | ||||

| Place of Origin | Dongguan | ||||

| size | The size in the picture can also be customized | ||||

13. Support customization:

14. Packaging:

15. Why choose us:

- Whether it's a bur for an Amann Girrbach Ceramill or a bur for a ZirkonZahn, we've got what you need from A to Z.

- ISO9001, ISO13485, CE, TUV certification achieved.

- More than 30 years of quality and innovation.

- Ready sample for your test within 7 days delivery. 24 hours/7 days support.

16. FAQ:

Q1 Are you a Manufacturer or a trading company?

We are an OEM & ODM original manufacturing supplier.

Q2 What's your delivery time?

1-2 days for Inventory product,

5 -7 days for out of stock products,

10-20 days for customized items.

Q3 How to order?

Step1 Send your inquiry to us.

Step 2 We quote you within 24 hours.

Step 3 Confirm the order.

Step 4 Do payment for the order.

Step 5 Delivery on time and tracking number notice.

Q4 Payment

We accept Visa, MasterCard, Alibaba trade assurance, T/T, PayPal, Western Union Money gram and L/C,

Q5 Shipping

We ship our tools worldwide using DHL, FedEx and UPS. If you would like to use your forwarder please call or send us an email and we will be glad to use your preferred carrier.

Q6 Quality

All of our tools come with a 100% satisfaction guarantee, if you are not completely satisfied with our tools, we will refund your money.